198th Electrochemical Society Meeting

MISFIT DISLOCATION NUCLEATION STUDY IN P/P+ SILICON

Petra Feichtinger1, Mark S. Goorsky1,

Dwain Oster2, Tom D'Silva2, and Jim Moreland3

1 Dept. Materials Science and Engineering UCLA, Los Angeles, CA

90025.

2 Wacker Siltronic Corp. Portland, OR 97210.

3 Wacker Siltronic AG 84489 Burghausen, Germany

A potential problem related with the p/p+ structure is that

high boron concentrations reduce the lattice parameter of silicon.1

Therefore, lightly doped epitaxial layers are compressively strained with

respect to the substrate and this strain can foster the formation of interfacial

misfit dislocations. This issue of strain relaxation becomes more problematic

with the industry push to lower resistivity substrates.

We studied misfit dislocation generation sites in epitaxial p/p+ silicon wafers.

These strain-relaxing defects nucleate heterogeneously at stress concentrators

at the lattice-mismatched interface. Different kinds of possible stress concentrators

have been identified to act in strained epilayer systems. In SiGe/Si, they

include b-SiC precipitates (due to insufficient

substrate cleaning)2, Ge-rich platelets2, oxide particles3,

diamond defects4, trace impurities of copper5, and crystal

defects at the wafer edges6. For III-V semiconductors, it has been

shown7 that highly dense threading dislocations in the substrate

bow out in the interface to form interfacial misfit dislocations in order

to relieve the misfit stress.

For hyper pure epitaxial silicon grown by highly clean CVD at very high temperature

(~ 1100 °C), most of these conditions do not apply. The threading dislocation

density is very small and particle contamination is extremely low. The wafer

edges have been shown to act as misfit dislocation nucleation sites in p/p+

silicon.8 Thus a challenge in the fabrication of defect free large

diameter silicon wafers for power MOS applications is the reduction of crystal

imperfections around the wafer edges.

We examined the effect of a variation of wafer edge treatments on misfit dislocation

formation in p/p+ silicon test wafers. The misfit in this system is low (~

1.6 * 10-4) compared to other strained epitaxial systems. The samples

were 150 mm Czochralski grown wafers with high boron doping level ([B] ~ 3*1019

cm-3). Differing treatments were used during the processing of

the test wafers to create a variation of mechanical damage around the substrate

wafer edges. A measure for the mechanical damage around the wafer edges was

gained using a profilometer. Nominally boron doped epitaxial layers ([B] ~

1*1015 cm-3) beyond the critical thickness were deposited

by vapor phase epitaxy at ~ 1100 °C in a single wafer reactor. The influence

of the residual crystalline damage around the test wafer edges on the appearance

of misfit dislocation segments was studied. Double crystal x-ray topography

was used to visualize the misfit dislocation segments around the wafer periphery.

The use of a curved first crystal allows the imaging of a large sample area

with uniform curvature.9

Figure 1 shows double crystal x-ray topographs of one series of test wafers.

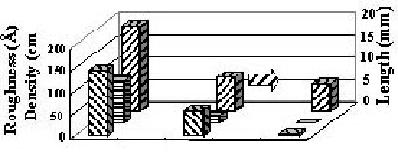

Figure 2 shows a graph of the measured data. As the roughness around the wafer

edge decreases, the misfit dislocation length and density decrease as well.

The total misfit dislocation length across the whole wafer decreases from

~ 20 m to ~ 0.1 m as the edge gets smoother.

We have shown that the wafer edge shaping and subsequent damage removal steps

determine the residual damage around the wafer edges, which during epitaxial

layer growth may act as misfit dislocation nucleation sites if not removed

prior to epitaxy. Edge treatments lowering the wafer edge roughness exhibit

a great reduction (<10 cm-1) or even the absence of misfit dislocations

compared to untreated edges (~1000 cm-1).

References:

1. H. Holloway and S. L. McCarthy, J. Appl. Phys. 73, 103 (1993).

2. D. D. Perovic and D. C. Houghton, Mat. Res. Soc. Symp. Proc. 263,

391 (1992).

3. C. G. Tuppen, C. J. Gibbings, and M. Hockley, J. Cryst. Growth 94,

392-404 (1989).

4. D. J. Eaglesham, E. P. Kvam, D. M. Maher, C. J. Humphreys, and J. C. Bean,

Phil. Mag. 59, 1059 (1989).

5. V. Higgs, P. Kightley, P. J. Goodhew, and P. D. Augustus, Appl. Phys. Lett.

57, 829 (1991).

6. M. Albrecht, S. Christiansen, J. Michler, W. Dorsch, H. P. Strunk, et al.,

Appl. Phys. Lett. 67, 1232 (1995).

7. J. W. Matthews and A. E. Blakeslee, J. Crystal Growth 27, 118-125

(1974).

8. H. Fukuto, P. Feichtinger, M. S. Goorsky, T. Magee, D. Oster, J. Moreland,

et al., J. Crystal Growth 209, 716 (2000).

9. M. S. Goorsky, P. Feichtinger, H. Fukuto, and G. U'Ren, Phil. Trans. R.

Soc. Lond. A 357, 2777 (1999).

Figure 1. Double crystal topographs taken at the wafer periphery of test

wafers. A difference in misfit dislocation density and length around the wafer

periphery depending on the roughness as a measure of residual damage around

the wafer edge is clearly visible.

Figure 2. Measured misfit dislocations length (mm), misfit dislocation

density (cm-1), and roughness data (Å) quantifying the double crystal topographs

in Figure 1.