Description

Closed-cell foams consists of gas bubbles separated one from another by a thin membrane of a continuous condensed phase. The condensed phase can be solid or liquid. Among foams having solid membrane, the polymeric foams are the most commonly used. They can be rigid or flexible and the cell geometry can be open or closed. Open-cell polymeric foams are generally flexible and best for automobile seats, furniture, and acoustic insulation. Closed-cell polymeric foams are usually rigid and mostly used for thermal insulation in the construction and refrigeration industries. Indeed, closed-cell foams are very effective thermal insulators due to entrapped blowing agents used for foaming and having a low thermal conductivity. Unfortunately, the thermal insulating properties and dimensional stability of rigid closed-cell foams decay significantly with age due to the outward diffusion of the low conductivity blowing agent and the inward diffusion of higher conductivity air constituents. Typically, air constituents diffuse through foam much faster than commonly used blowing agents such as chlorofluorocarbons. As a result, the short and intermediate term aging of polymeric foams are due to in-diffusion of air constituents, while long-term aging depends on depletion of blowing agents.

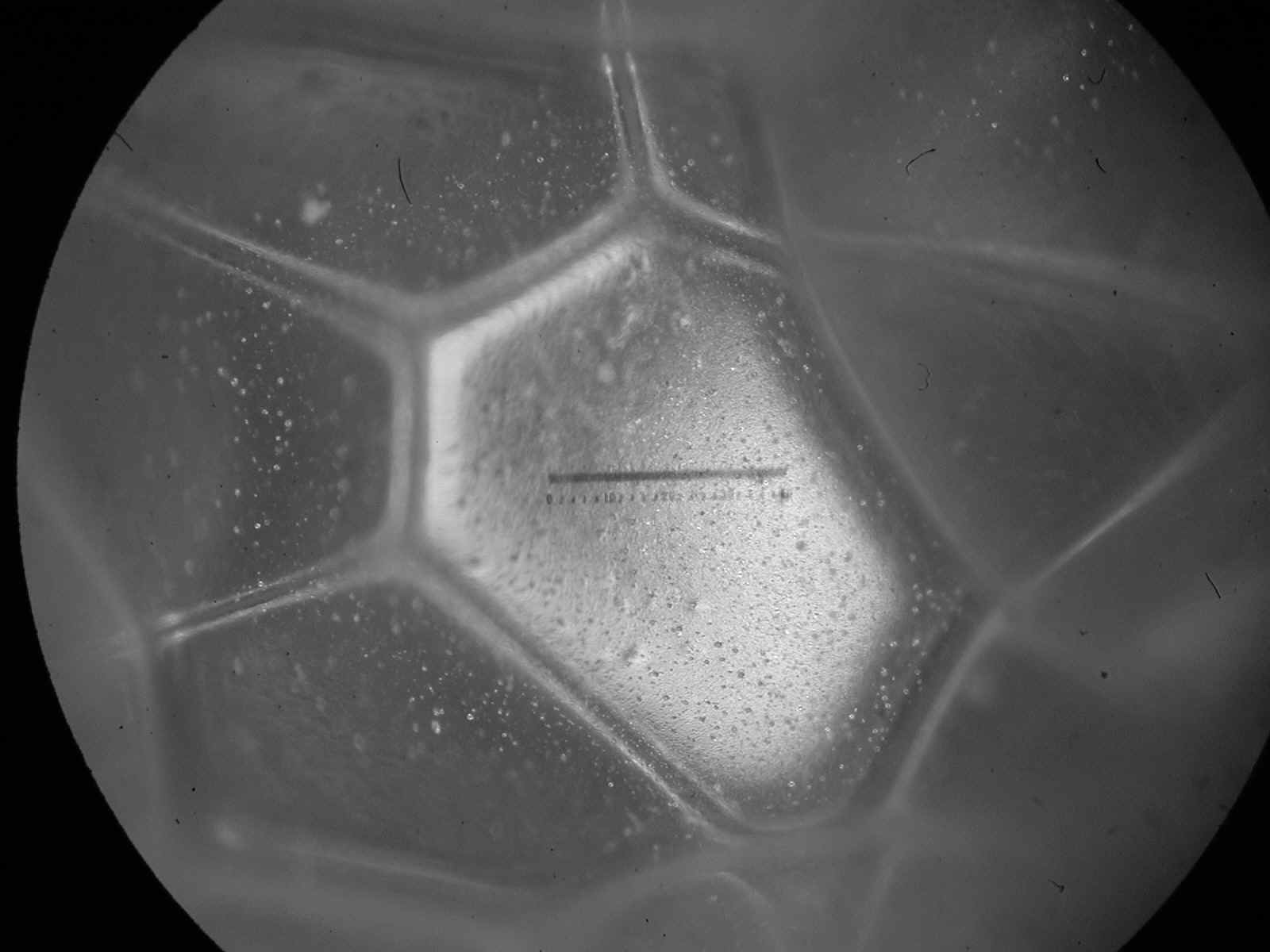

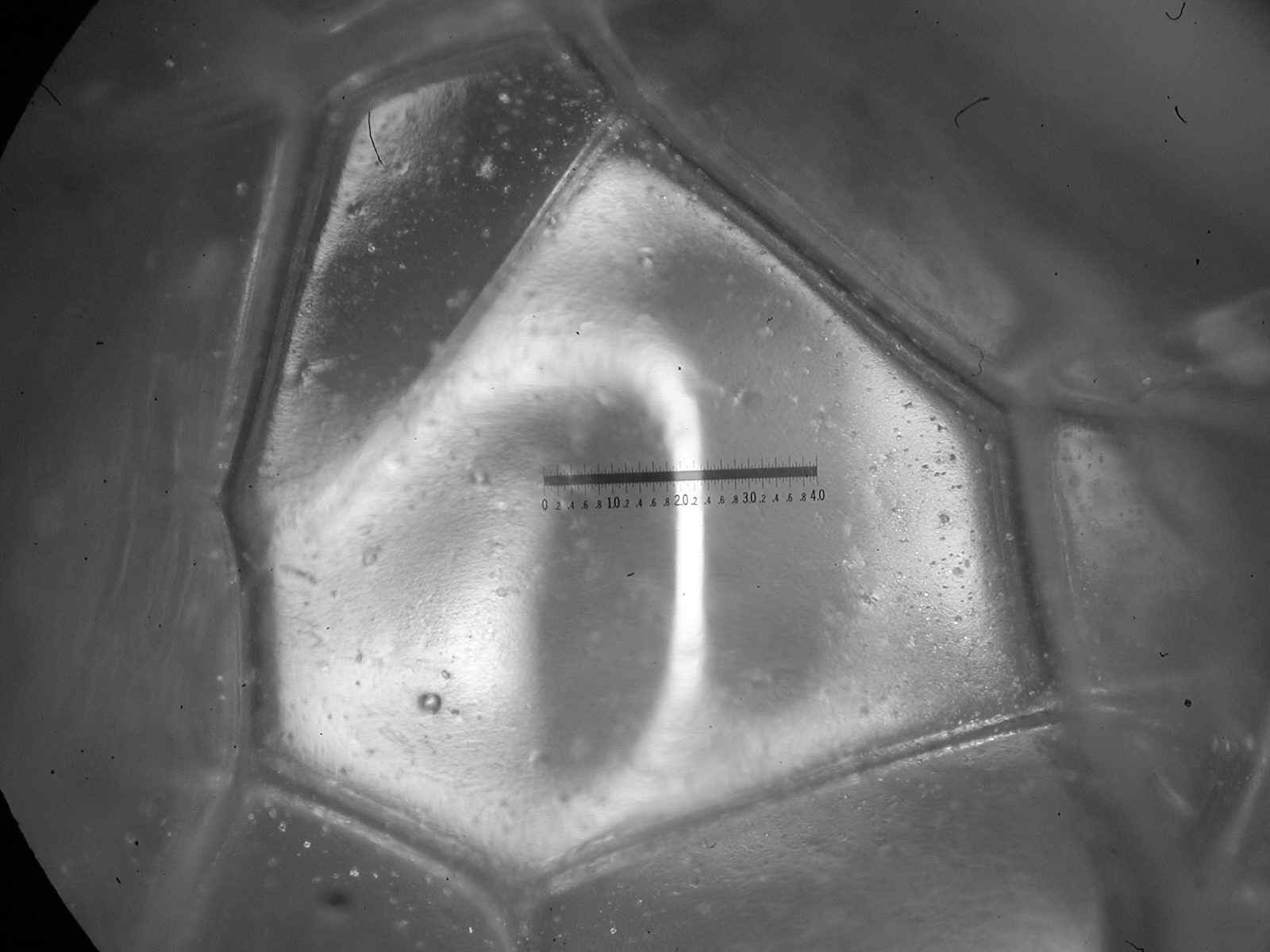

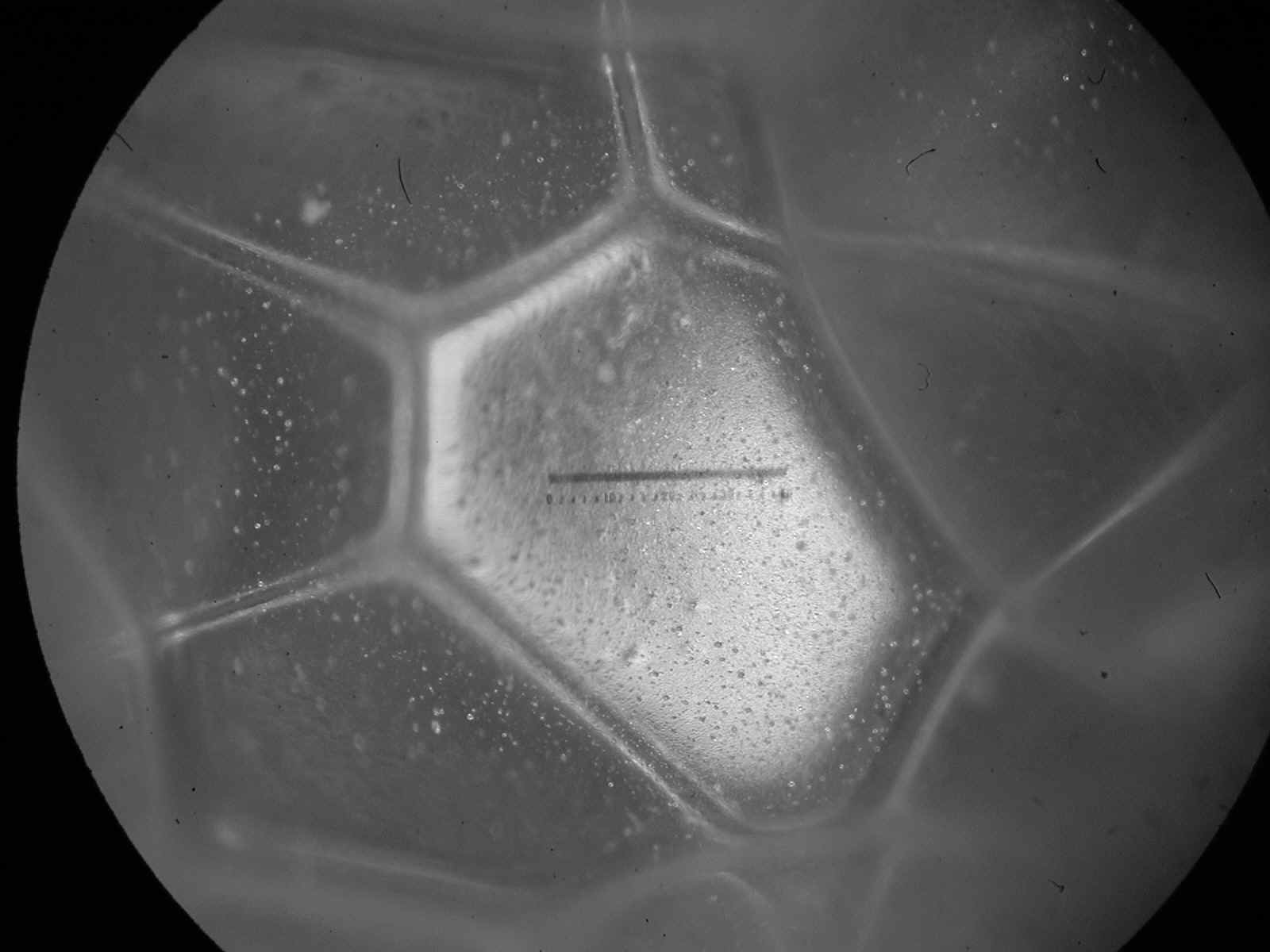

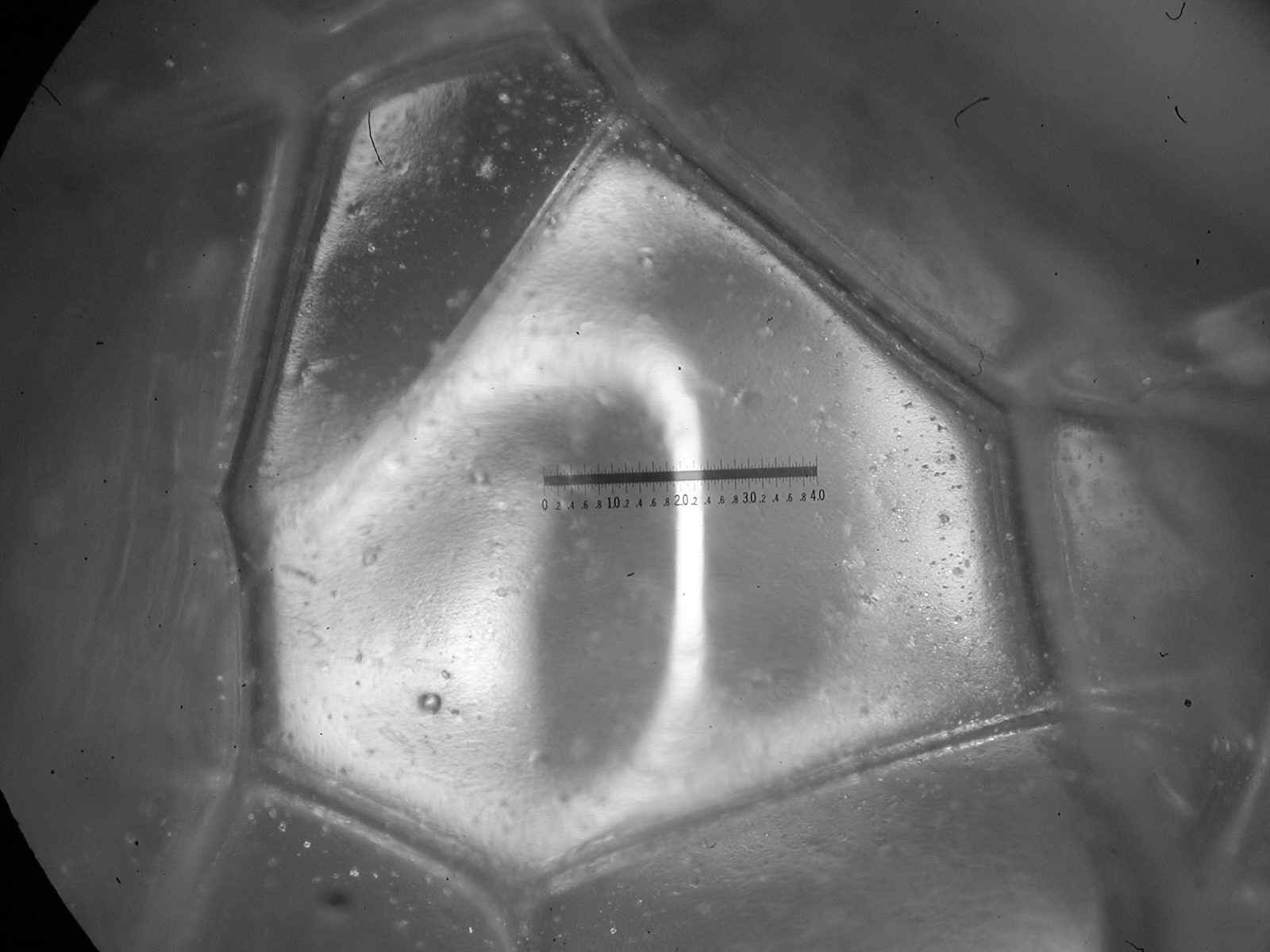

Figure 2: Morphology of lamellae of polyhedral bubbles in closed-cell rigid polyurethane foam by optical microscopy.

This topic gained interest after the Montreal protocole that banned the use of chlorofluorocarbons (CFC) as filing gases for insulation foams and refrigerants. The challenge is to find new efficient and environmentally friendly gases to replace the CFCs. The objective of this project is to develop an engineering model based on fundamentally sound but simplified treatment of mass diffusion phenomena for practical predictions of the effective diffusion coefficient of gases through a foam layer.

Relevant Publications