Superficial Gas Velocity for Onset of Foaming

Whether foam is desirable or not, it is of fundamental and practical interest to understand the foaming process and to predict the conditions under which foam starts forming in order to operate a process under the most desirable conditions, the minimum superficial gas velocity for onset of foaming should be determined as a function of the thermophysical properties of the two phases and the operating conditions. However, to the best of our knowledge, no quantitative analysis for predicting jm is available in the literature.

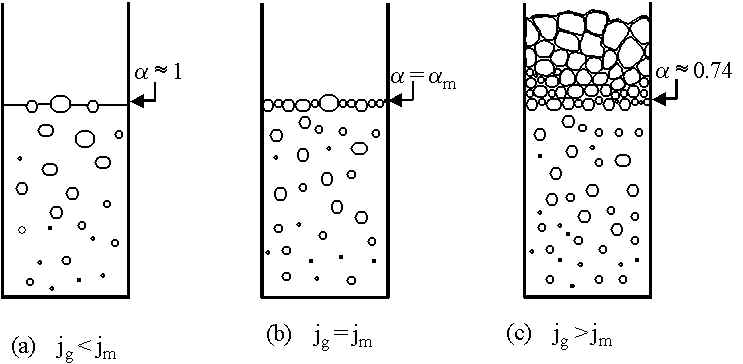

Figure 1: Schematic of the behavior of a foaming solution as the superficial gas velocity is increased (a) bubbly flow without foam, (b) onset of foaming, (c) developed foam layer.

This project aims to better understand and predict the conditions for onset of foaming of semi-batch foams by developing a quantitative self-contained model giving the minimum superficial gas velocity as a function of the thermophysical properties of the two phases and the operating conditions.

Publications

L. Pilon and R. Viskanta, 2004. Minimum Superficial Gas Velocity for Onset of Foaming. Chemical Engineering and Processing, Vol.43, No.2, pp.149-160. doi:10.1016/S0255-2701(03)00012-6