This project aims at improving the performance of vinylidene fluoride-trifluoroethylene P(VDF-TrFE) copolymer for pyroelectric infrared detection and direct thermal to electrical energy conversion. Solvent extraction was used to purify the copolymer while phase inversion was utilized to introduce pores into the copolymer matrix. Previously, a partial material characterization was performed on purified P(VDF-TrFE) that suggested its usefulness for energy harvesting. Here, full characterization of the thermophysical and electrical properties relevant to pyroelectric infrared detection and energy conversion of both purified and porous P(VDF-TrFE) thin films is presented. Properties measured include (1) density, (2) ferroelectric to paraelectric phase transition temperature, (3) enthalpy of change of phase, (4) electrical resistivity, (5) ferroelectric hysteresis, as well as (6) specific heat, (7) dielectric constant, (8) loss tangent, and (9) pyroelectric coefficient as a function of temperature.

Synthesis

The following illustrations detail the processes for synthesizing (i) dense films from commercial P(VDF-TrFE) pellets, (ii) purified films, and (iii) nanoporous films used in this study. The process for all films uses the commercial copolymer of 60/40 P(VDF-TrFE).

Commercial Dense P(VDF-TrFE) Films

Purified P(VDF-TrFE) Films

Porous P(VDF-TrFE) Films

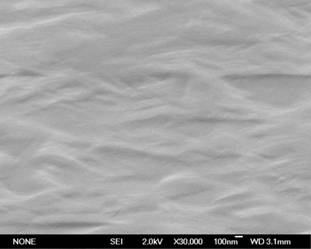

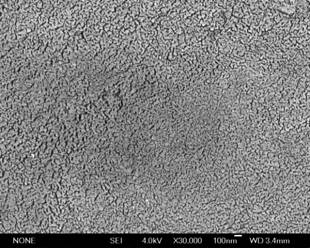

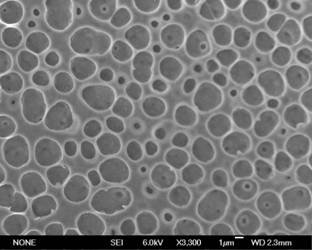

SEM images

Porous films had pores with an average diameter of 2.2 µm with a standard deviation of 0.8 µm. Note that measurements made on the top surface of the film and serves only as an approximation to the actual pore size.

The specific heat cp was measured by heating each film from 30 to 100°C, followed by cooling from 100 to 30°C. The results are shown in the figure below.

During heating, the heat transfer rate exhibited peaks for the commercial, purified, and porous films at 65.7, 65.1, and 66.9°C, respectively. These peaks represent the ferroelectric to paraelectric phase transition of each material. Similarly, during cooling, the commercial, purified, and porous films exhibited peaks at 59.7, 59.8, and 60.3°C, respectively. The peaks represent the paraelectric to ferroelectric phase transition. In addition, the results reveals that (1) the ferroelectric to paraelectric phase transition upon heating occurred at a higher temperature than the paraelectric to ferroelectric phase transition upon cooling and (2) both transitions occurred over a relatively wide temperature range.

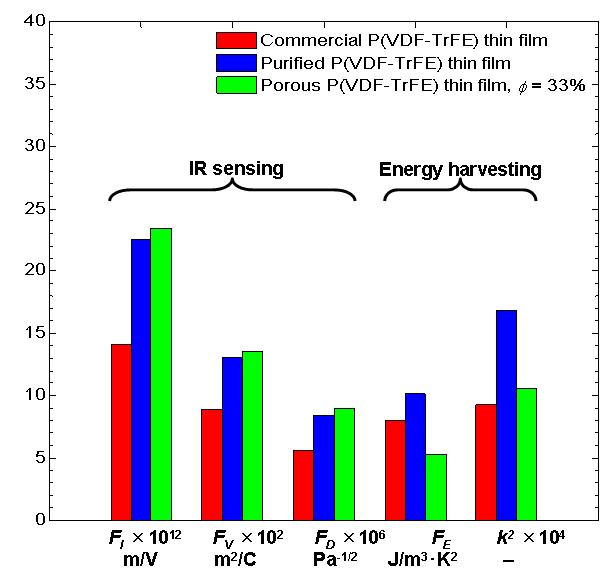

Different figures of merit (FOM) exist to assess the performance of pyroelectric materials depending on the application considered. For infrared detectors, the (1) voltage FV, (2) current FI, and (3) noise FD figures of merit are defined as,

![]()

FV gives a measure of the ratio of the output voltage response of the detector to the input power defined as the radiation incident on the surface of the detector. Likewise, FI represents the pyroelectric current generated per watt of input power. The third figure of merit, FD, quantifies electrical noise caused by thermal energy (Johnson noise), usually the primary source of noise in pyroelectric infrared detectors.

For energy harvesting, two figures of merit have been proposed, namely FE and k2 defined as,

where Thot is the temperature of the hot source. FE represents how much electrical power a pyroelectric material can harvest from the hot source while k2 is a dimensionless electrothermal coupling factor that represents how effectively a pyroelectric material converts thermal energy into electrical energy.

The figure below plots each figure of merit at room temperature for each type of film. In addition, Note that 100°C was chosen for Thot in the computation of k2.

The figures of merit for infrared detection FV, FI, and FD were improved by 47.0, 59.6, and 51.6%, respectively for the purified film while the porous film with porosity of 33% showed an improvement of 52.8, 66.3, and 62.6%, respectively when compared to those of a dense commercial P(VDF-TrFE) film. In addition, figures of merit for energy harvesting FE and k2 indicate that the purified and porous films are attractive for thermal to electrical energy conversion as well.

This work aimed at characterizing the electrical and thermophysical properties of 60/40 P(VDF-TrFE) to help achieve higher performance for pyroelectric IR detectors and energy harvesting devices. Commercial, purified, and porous P(VDF-TrFE) films were synthesized and characterized. It was established that:

- the peak temperature during the ferro- to paraelectric and para- to ferroelectric phase transition was around 65.9 and 59.9°C, respectively for all films. This established that neither purification or the presence of pores in the matrix had a large affect on the phase transition temperatures.

- the ferro- to paraelectric and para- to ferroelectric phase transition took place over a temperature range nearly the same for all films and equal to 22.6°C between 53.3 and 75.9°C and 22.3°C between 43.4 and 65.7°C, respectively.

- the phase change enthalpy during the ferro- to paraelectric and para- to ferroelectric phase transitions for purified and porous films was about 28 and 18% lower than that of the commercial film, respectively.

- the specific heat of the porous and purified films was comparable to one another and smaller than that of the commercial films.

- electrical resistivity measurements determined that the commercial films had the highest resistivity (54.1

), followed by the purified (20.6

), followed by the purified (20.6  ) and then porous film (7.5

) and then porous film (7.5  ). The lower resistivity of the purified and porous films can be attributed to the presence of pores in both films which creates non-uniform electric fields in the films.

). The lower resistivity of the purified and porous films can be attributed to the presence of pores in both films which creates non-uniform electric fields in the films. - the ferroelectric hysteresis curves established that all films had about the same coercive field of Ec = 30.5 MV/m. Moreover, the purified and porous films exhibited larger polarization than the commercial films.

- At room temperature, the pyroelectric coefficient for the commercial, purified, and porous films was 4.5, 5.1, and 4.3

, respectively.

, respectively. - The pyroelectric coefficient for all films reached a maximum at 50°C corresponding to the start of the ferro- to paraelectric phase transition.

- for all temperatures below the start of the phase transition, the purified films had the largest pyroelectric coefficients that were on average about 32% greater than that of the commercial films while the porous films had the smallest values.

- the figures of merit for infrared detection FV, FI, and FD were improved by 47, 60, and 52%, respectively for the purified films. The porous films with 33% porosity showed an improvement of 53, 66, and 63%, respectively.

- the energy harvesting figures of merit FE was greater than that of the commercial films due to its larger pyroelectric coefficient. However, FE for the porous films was smaller than for the commercial films due to its smaller pyroelectric coefficient.

- The factor k2 for the purified and porous films was 80.7% and 14.8% greater than that of the commercial films, respectively. The importance was due to the reduction in heat capacity and to the larger pyroelectric coefficient of the purified films.

The results suggest that low grade waste heat energy harvesting achieved with purified and porous films can be more efficient than with the commercial films.

A. Navid, C.S. Lynch, and L. Pilon, 2010. Synthesis and Characterization of Commercial, Purified, and Porous Vinylidene Fluoride-Trifluoroethylene P(VDF-TrFE) Thin Films . Smart Materials and Structures, Vol. 19, pp. 055006(1-13).